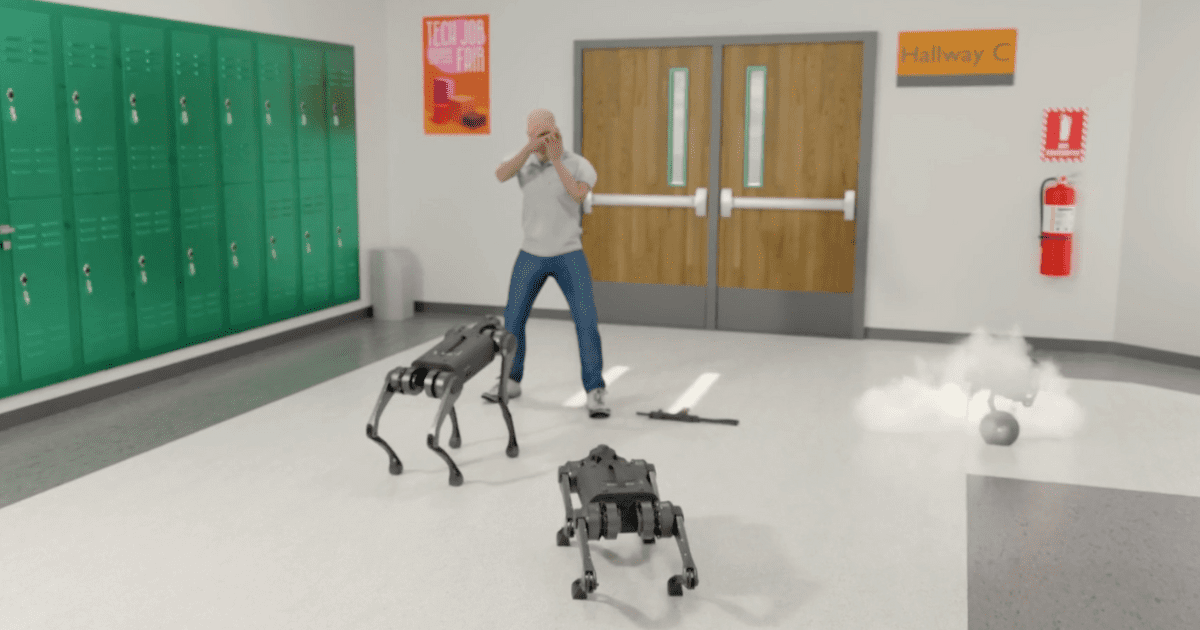

Industry 4.0 is technology-driven, whereas Industry 5.0 is value-driven. It is important to remember that Industry 4.0 and Industry 5.0 are mutually complementary, not mutually exclusive. This next wave of the industrial revolution needs to define how we collaborate and define the rules between human and AI interaction.

As the manufacturing industry enters its fourth revolution, innovations such as robotics, automation and artificial intelligence are set to take over. Automation continues to create new types of robots with improved utility and function. Future factories will feature robots and humans working side-by-side to meet consumer demand. A major benefit of automation in large manufacturing operations is that some tasks could be completed 24/7, thereby boosting production output without any additional labor costs. This automation will lower overhead costs substantially. In addition, many advanced robotics require only a small amount of space to operate and can safely work alongside humans on assembly lines. The reduction in required space means that companies could also downsize to cheaper workplaces and factories. Robots are not replacing human workers but allow workers to focus on more intensive duties while the robots are taking on repetitive tasks. In fact, the increased use of AI in the workplace may create new jobs, allowing employers to hire more staff in the future.

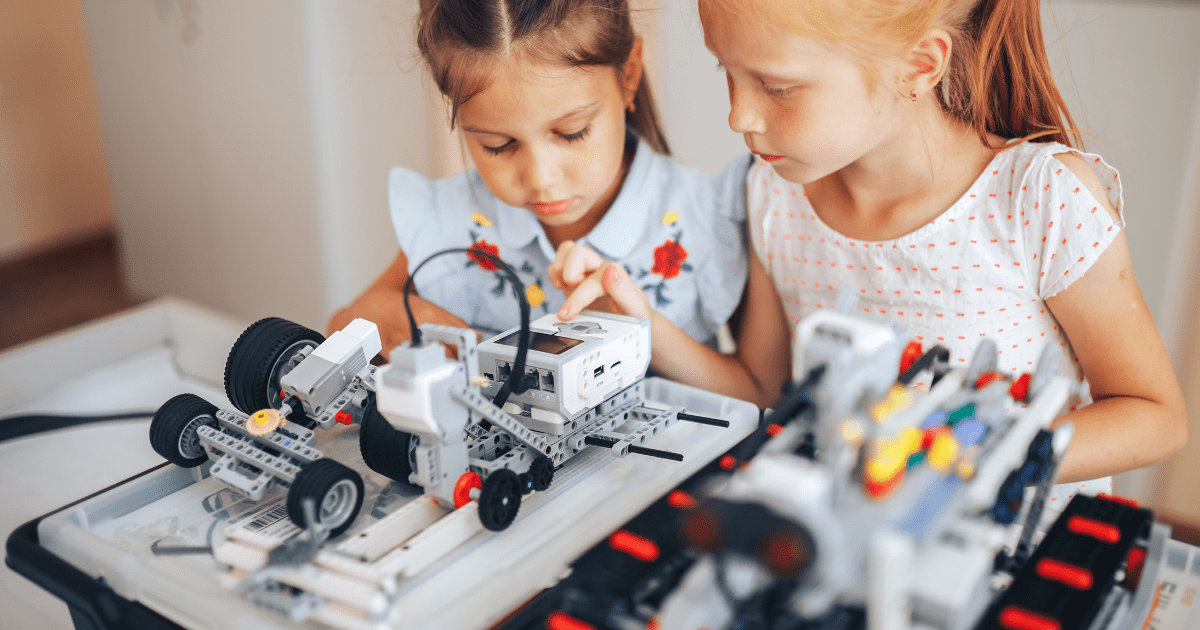

In contrast to Industry 4.0, Industry 5.0 aims to put the human touch back into development and production. Industry 5.0 is all about granting human operators the benefits of robots such as technical precision and heavy-lifting capabilities. Consumers want mass personalization, which can only be had when the human touch returns to the manufacturing industry. Industry 5.0 puts more attention on highly skilled people and robots working side-by-side to create individualized products. Collaborative robots (cobots) are exactly the tools companies need to produce the personalized products consumers demand today. Cobots bring the human touch to the masses. Industry 5.0 reflects a growing view amongst manufacturers of the need to respond to increasing demand amongst customers for a higher degree of individualization. The main driver behind the rise of industrial robots is the desire to reduce or eliminate the dull, dangerous jobs.

Key Points:

Industry 4.0

• Focus on equipment connectivity

• Mass personalization

• Smart Supply Chain

• Smart Products

• Remote Workforce

Industry 5.0

• Focus on Customer Experience

• Hyper-Customization

• Responsive & Distributed Supply Chain

• Interactive Products

• On-Site Workforce