Efficiency, safety, and productivity are essential in the fast-paced manufacturing world. Stokes Robotics transforms into the spotlight, offering cutting-edge robots redefining manufacturing processes. These robots are not just mere mechanical arms; they are game-changers that can revolutionize manufacturing facilities’ operations. With a focus on improving safety, increasing productivity, and reducing labor costs, Stokes Robotics’ robots bring a futuristic touch to the manufacturing world. Explore how these innovative robots can enhance your manufacturing facility and operations.

A Technological Leap in Manufacturing

Stokes Robotics empowers manufacturing facilities with state-of-the-art robotic solutions that optimize operations and elevate overall performance. Robots are vital assets, simplifying complex tasks and streamlining everyday operations, ultimately fostering a safer, more productive, and more efficient manufacturing environment.

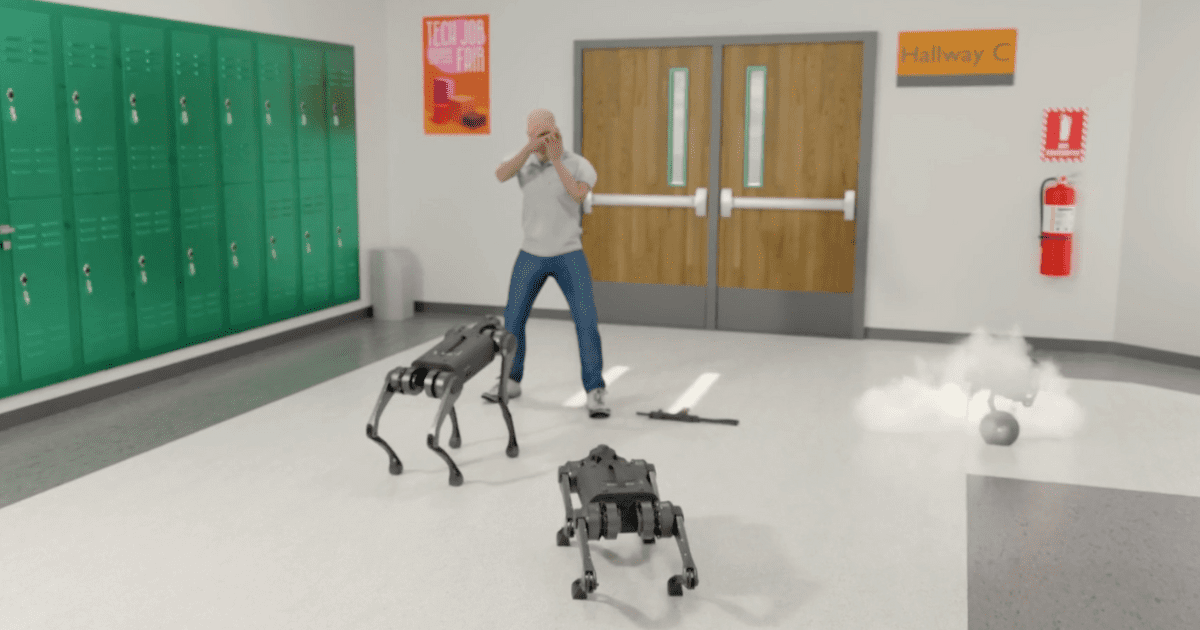

Enhancing Safety and Reducing Labor Costs: Safety is paramount in manufacturing, and Stokes Robotics’ robots are designed to enhance safety measures within the facility. By automating hazardous or repetitive tasks, these robots reduce the risk of accidents and injuries, ensuring a safer working environment for your workforce. Additionally, with their ability to handle labor-intensive duties, the robots can effectively reduce labor costs, maximizing operational efficiency and cost-effectiveness.

Efficient Inventory Management: Managing inventory is a critical aspect of manufacturing, and our robots excel in this area. Robots can autonomously manage and update your inventory, ensuring accurate and real-time information on stock levels. Manufacturers can optimize supply chain processes and reduce inventory-related inefficiencies with improved inventory management.

Predictive Maintenance and Problem Solving: Stokes Robotics’ robots go beyond the ordinary by offering predictive maintenance capabilities. Equipped with advanced sensors, these robots can detect machines that need maintenance based on sound and other indicators, resolving potential issues before they escalate. Manufacturers can minimize downtime and prevent costly breakdowns by implementing predictive maintenance, increasing productivity and efficiency.

Gas Leak Detection and Hazard Prevention: In manufacturing facilities with hazardous substances, gas leaks can pose significant risks. Stokes Robotics’ robots are equipped to check for gas leaks and promptly alert personnel in case of any potential hazards. This proactive approach to hazard prevention helps safeguard the facility and its workforce, mitigating potential risks and ensuring a secure working environment.

Creating a Smarter & Safer Manufacturing Environment

Integrating Stokes robots into manufacturing represents a monumental shift in how factories operate. By embracing these advanced robots, manufacturers can achieve a future of streamlined operations, enhanced safety, and heightened productivity.

Maximizing Productivity & Efficiency:

With robotics at the core of manufacturing operations, factories can achieve unprecedented productivity and efficiency. The robots’ ability to work autonomously, conduct predictive maintenance, and streamline inventory management translates into a more streamlined manufacturing process.

Step into the Future with Stokes Robotics

From safety enhancement to predictive maintenance and efficient inventory management, Stokes Robotics is revolutionizing the manufacturing industry with innovative robotics. Incorporating these advanced robots into your facility opens the door to a new era of smarter, safer, and more productive manufacturing.